安全的, Highly Reliable Power

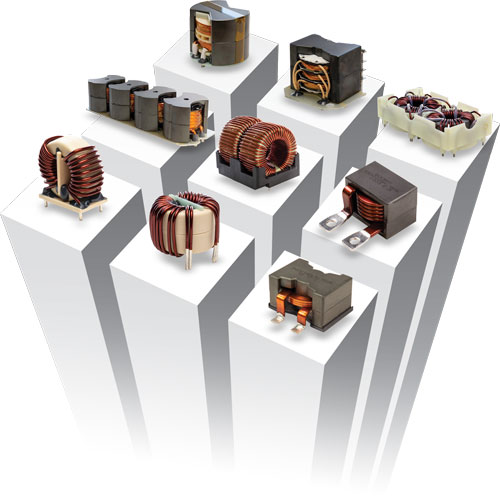

With more than 25 years of Magnetic components experience, Prowell Techology offers a broad, proven and continually expanding portfolio of catalog and modified standard products as well as extensive capabilities for the development of fully customized components. Our advanced magnetics components are designed to meet essential power application requirements for:

- Power conversion

- Isolation

- EMC compliance

- Signal integrity

- Increased power density

Helping to ensure efficient and safe, highly reliable power, Prowell Electric Magnetics are key elements in many of today’s breakthrough electric vehicle, high power battery charging, e-mobility, renewable energy, energy storage, Internet of Things (IoT) and industrial infrastructure designs.

We developed our comprehensive Magnetics line to make it easy for circuit designers to select the right components to meet their increasingly complex and demanding application requirements. And, our roadmap remains strong in addressing next-generation application needs.

Contact Prowell Electric today for your Magnetic component requirements.

Prowell Electric Catalog Magnetic Components

For today’s rugged design requirements, we offer a full range of automotive grade Magnetics components

For today’s rugged design requirements, we offer a full range of automotive grade Magnetics components

- High creepage and clearance isolation transformers

- BMS signal transformers

- Chip LAN transformers

- Power inductors

- AEC-Q200 High Current Common Mode Chokes

Prowell Electric Magnetics Design Differentiators

Our extensive Magnetics experience allows us to meet the requirements in today’s designs that operate at higher switching frequencies, require ever-more component performance support and are continually shrinking in size.

- Miniaturization – Smaller form factors for space-constrained designs

- Low EMI noise – Inductors that mitigate EMI noise while maintaining high efficiency

- Thermal management – Industry leading temperature stability

- High robustness and reliability — Helps maximize product lifespan

- Advanced materials and construction for highly efficient and ultra-low DC resistance –

- advanced metal alloy powder cores

- molded construction techniques

- flat windings

- self-lead terminals

Custom Magnetic Capabilities

From Design to Spec and Build to Print — all the way to Volume Production.

普罗威尔电气’ custom Magnetics team can design and manufacture transformers and inductors for almost any power level, helping designers meet their application specific requirements. Customers are able to leverage Prowell Electric’ engineering expertise and advanced software design tools to expedite the development an optimized design. Plus, our engineering lab can provide fast turnaround prototype samples and manufacturing to support volume production goals.

The proof is in the thousands of successful fully custom designs Prowell Electric has delivered:

- High power SMPS transformers (1 kilowatt to high power 25 kilowatt and higher)

- High voltage isolation, TH and SMT transformers to meet UL and IEC requirements

- SMPS transformer designs for a wide range of operating frequencies

- High current inductors for any Magnetics application

- Semi and fully customized EMC/EMI components

Key expertise includes:

- Fast prototypes

- Ferrite core manufacturing

- Designs for EMI reduction

- Expertise in thermal management

- Engineering support for finite element analysis and simulations

- Comprehensive custom design capabilities including:

- standard and custom bobbins and cores

- aluminum housings

- thermally conductive potting

- Litz wire

- flat wire windings

Agency Standards Compliance

Prowell Technology designs for compliance with UL and IEC safety standards for isolation and creepage and clearance. We can also meet customers’ strict automotive grade requirements including AEC-Q200 and PPAP.

Electric transformer manufacturer

helloI really like your writing so a lot share we keep up a correspondence extra approximately your post on AOL I need an expert in this house to unravel my problem May be that is you Taking a look ahead to see you.

I genuinely appreciated what you’ve achieved here. The outline is tasteful, your written content fashionable, yet you appear to have acquired some uneasiness regarding what you wish to present forthwith. Undoubtedly, I’ll return more frequently, similar to I have almost constantly, should you sustain this upswing.

The breadth of knowledge compiled on this website is astounding. Every article is a well-crafted masterpiece brimming with insights. I’m grateful to have discovered such a rich educational resource. You’ve gained a lifelong fan!